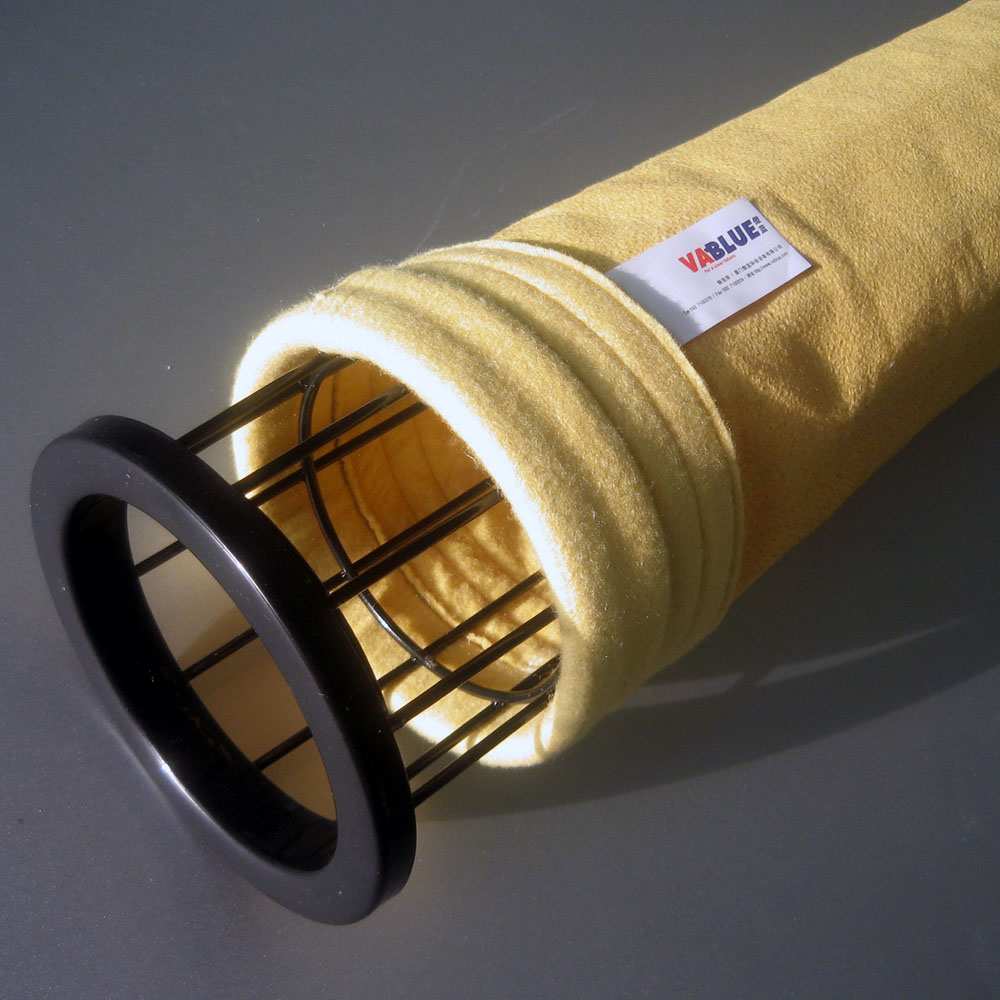

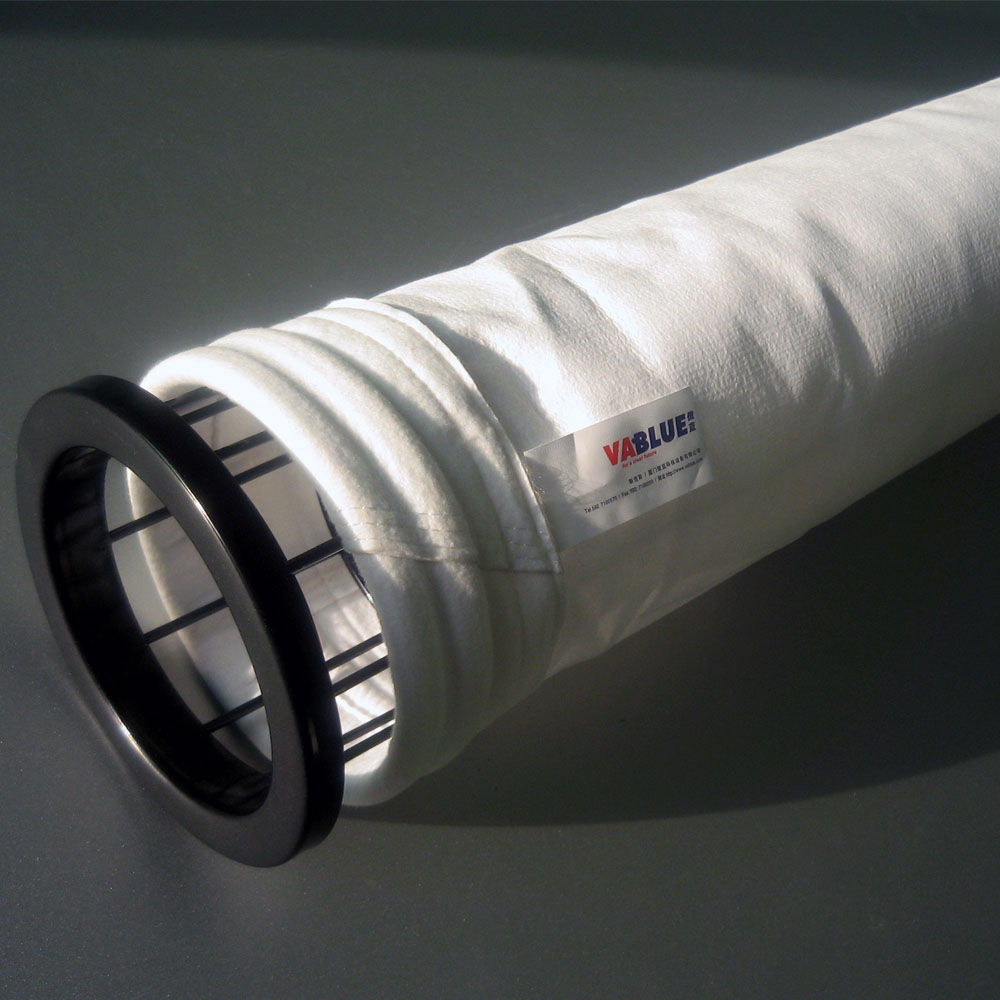

Description

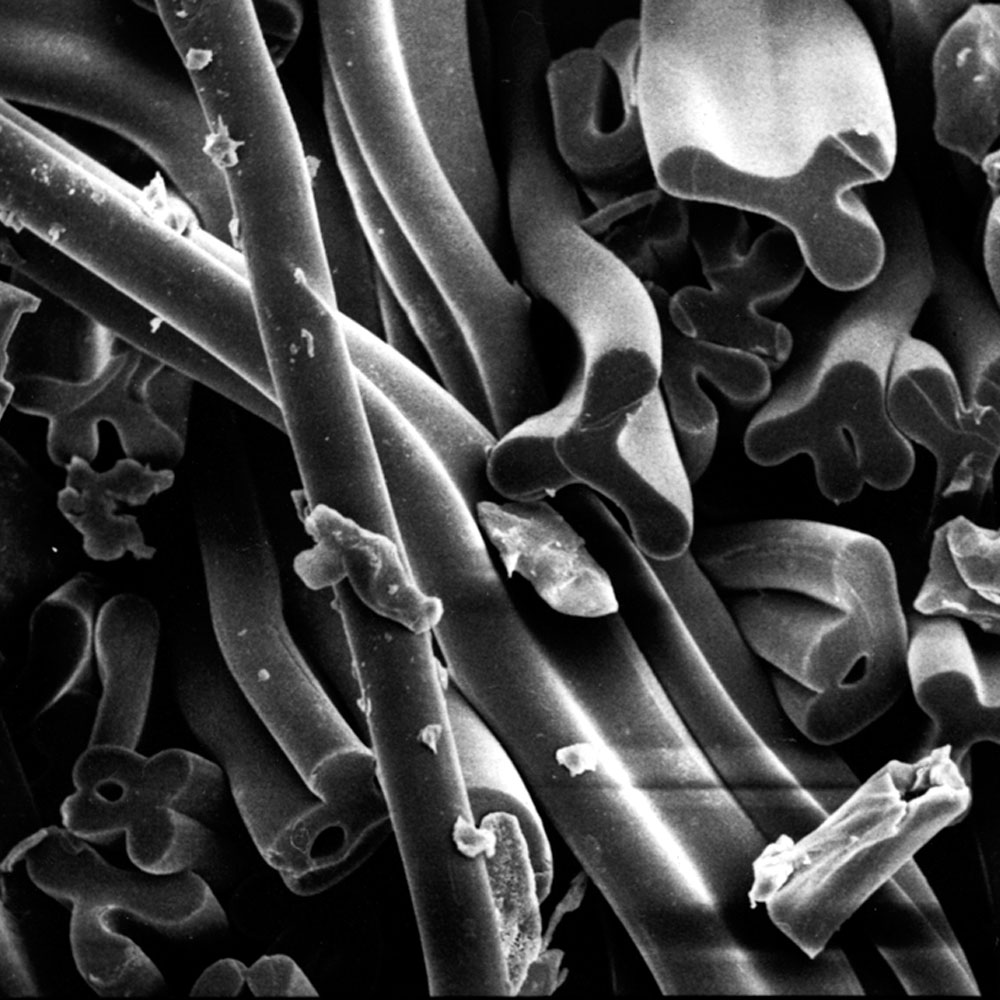

P84 fiber is a special-shaped (trilobal) cross-section structure, which has a large filtration surface area and excellent filtration performance. Therefore, P84 fiber is often implanted into the surface layer of filter material (dust facing side to improve the filtration performance of filter material)

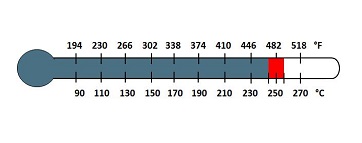

Maximum Continuous in Dry Conditions: 245°C / 473°F

Maximum Surge in Dry Conditions: 255°C / 491°F

Product features

Remarkable temperature resistance

Good chemical resistance

Low backwash pressure and high cake removal efficiency

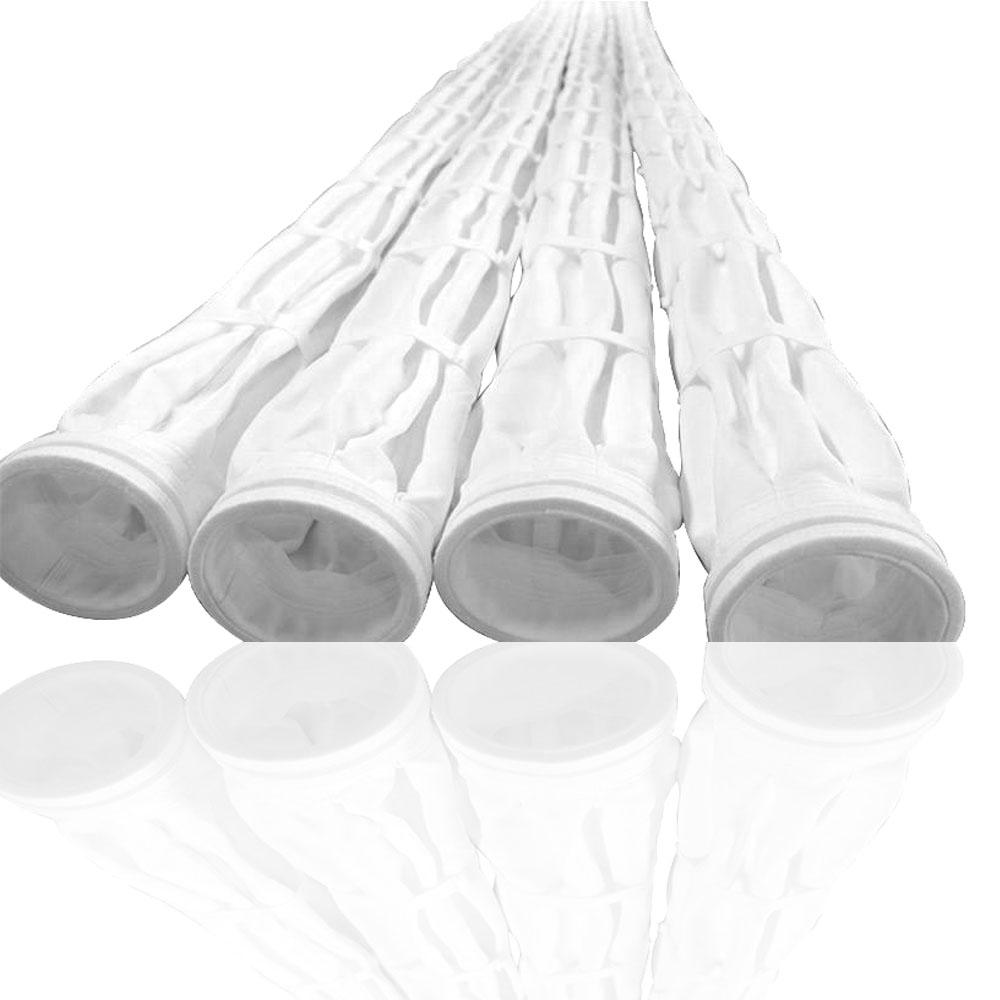

Typical applications

P84 is mainly used for flue gas purification in asphalt mixing, cement kiln, drying, combustion, smelting, various industrial kilns, coal-fired boilers and waste incineration, and is widely used in processes with high emission concentration requirements

Technical parameter

Product name P84 / P84 a500sg

Fiber 100% P84

Substrate 100% PTFE

Weight per square gram 500g / m2

The thickness is 2.1 mm

Density 0.24g/cm3

Air permeability 180L / dm2.min

Fracture strength - longitudinal ≥ 800 n / 5cm

Fracture strength transverse ≥ 800 n / 5cm

Elongation @ 200N / 5cm - longitudinal < 5%

Elongation @ 200N / 5cm - transverse < 5%

Thermal shrinkage @ 260degc, 90min, 1.5%

Blasting strength > 300 n / cm2

Service temperature

Continuous working temperature 240 ℃

Instantaneous working temperature 260 ℃

Post treatment, heat setting, burning and pressing