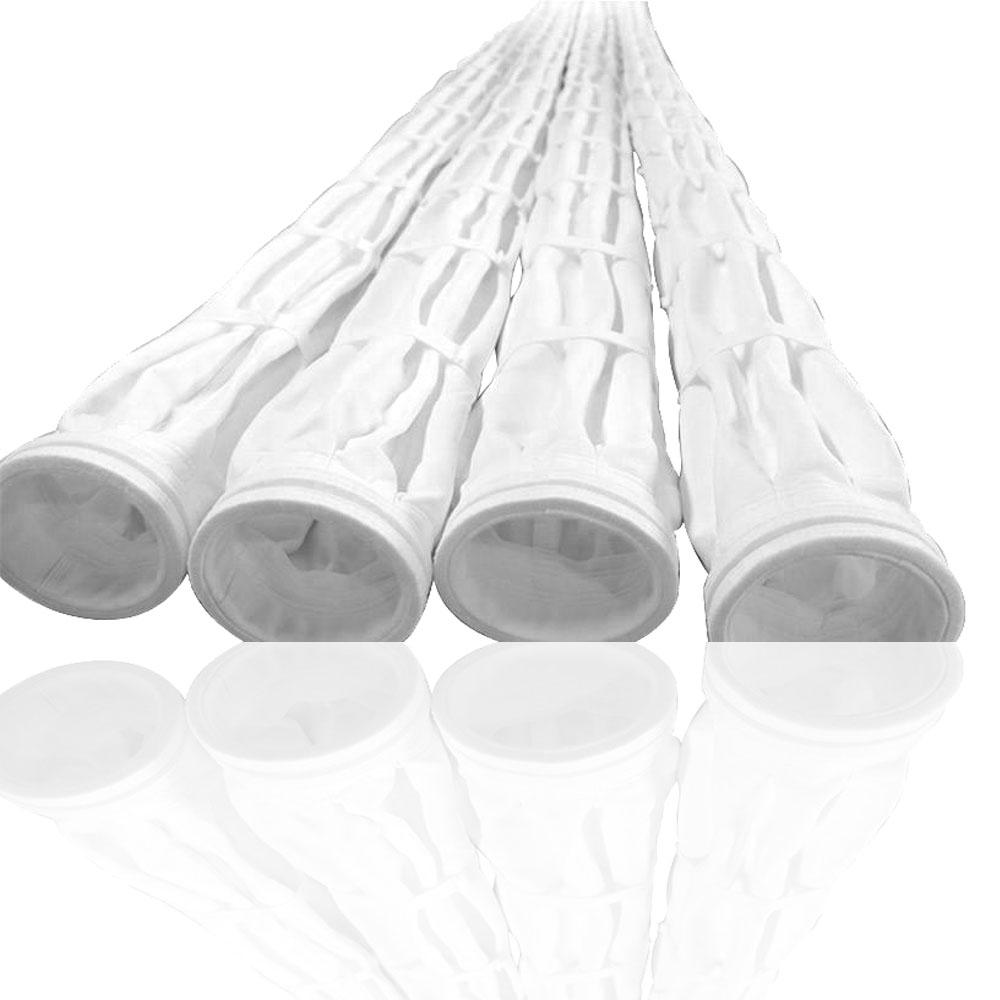

Description

Compared with the ordinary filter bag, the filter bag after water repellent and oil proof treatment has longer service life, longer ash cleaning period and larger gas flow rate because the filter material is not easy to block the paste bag. Therefore, the energy consumption and maintenance cost can be greatly saved, and the output can be increased.

Product features

1. Using special water splashing agent, its oil and water proofing function is better and more durable, and it can still maintain good oil and water proofing performance at 250 ℃.

2. Advanced equipment is used for post-treatment. During the treatment, all fibers absorbed certain additives, then dried at a certain temperature, and finally baked at a higher temperature. In this way, the fabric can keep good oil and water resistance after repeated ash cleaning and even water washing.

3. Improve the ash cleaning performance and improve the safety under discontinuous working condition. Even in the discontinuous working state, when the temperature drops below the dew point, the oil and water-proof filter material can still prevent moisture from gathering on the needled felt, so as to reduce the risk of excessive dust hardening and solidification on the needled felt

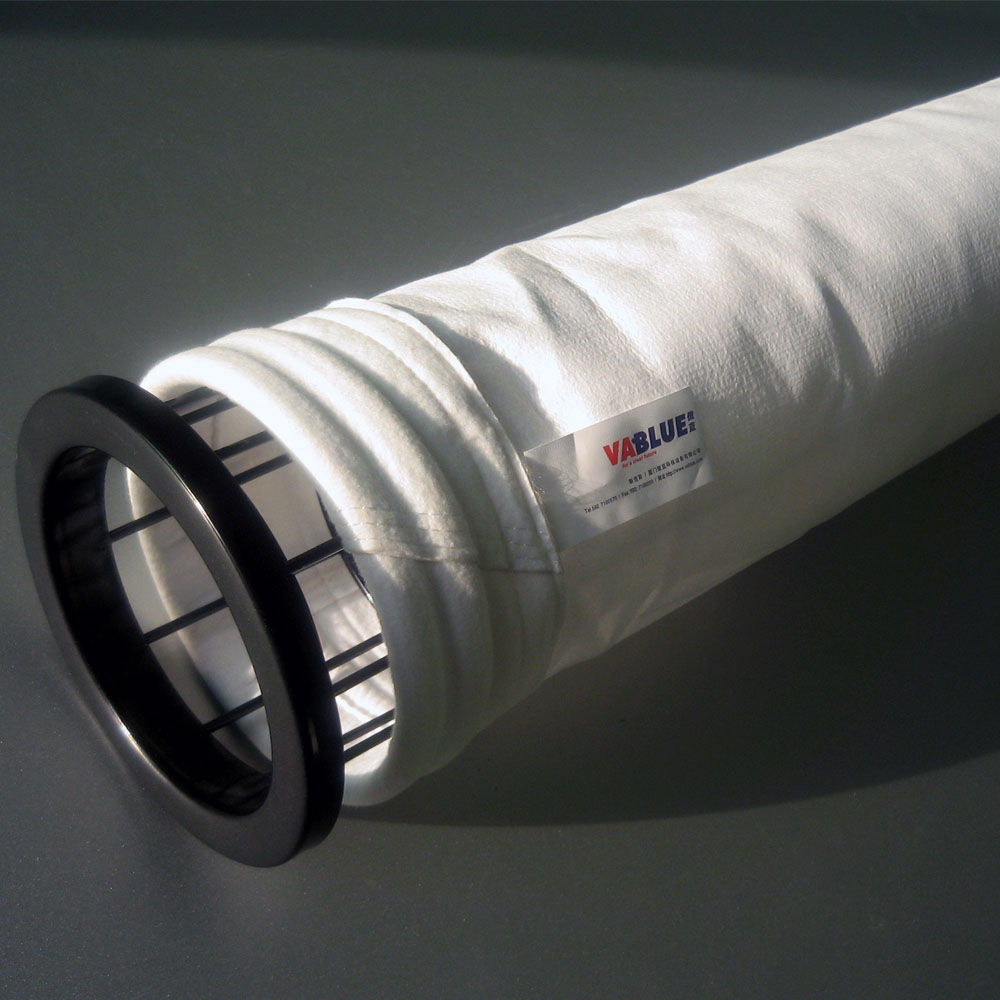

Technical parameter

Product name PE / PE a500sg-3

Fiber 100% pet

Base cloth 100% pet

Weight per square gram 500g / m2

Thickness 1.7mm

Air permeability 130L / dm2.min

Fracture strength - longitudinal ≥ 1200 n / 5cm

Fracture strength - transverse ≥ 1500N / 5cm

Elongation @ 200N / 5cm - longitudinal ≤ 5%

Elongation @ 200N / 5cm - transverse ≤ 5%

Thermal shrinkage @ 150degc, 90min ≤ 1%

Blasting strength ≥ 300 n / cm2

Service temperature

Continuous working temperature 130 ℃

Instantaneous working temperature 150 ℃

After treatment heat setting, burning pressure, anti oil and water treatment

Notes

The oil-water proof filter bag can do the following post-treatment according to the needs to meet the needs of different working conditions

Antistatic

Surface treatment of fine denier fiber

Film mulching

coating