Description

Before the combustion or production process of precoating, cut off and stop the ash cleaning system, and open the air inlet valve of the dust collector (including the air inlet and outlet valves of each filter bag chamber).

Operation process

1. Bag precoating is carried out by using induced draft fan before boiler ignition;

2. When the bag is pre coated, ensure that the ash cleaning system does not work;

3. Connect the ash conveying pipe of the special tank car filled with fly ash to the connecting pipe of the pre spraying device, and seal the compression interface.

4. Start up two boiler induced draft fans, and the fan opening increases gradually to more than 40%. Start the fan to gradually increase the air flow of the dust collector until it reaches the design air volume, and record the resistance inside and outside the filter bag of each room.

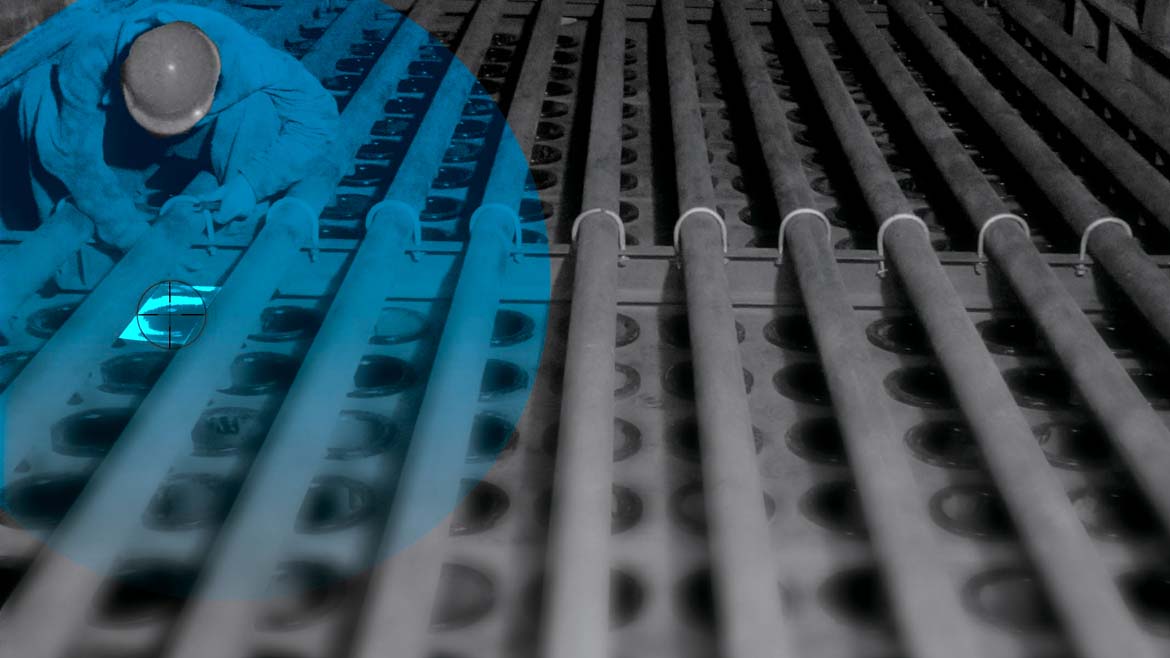

5. First, open the corresponding entrance and exit damper doors of one channel in the same flue, close the entrance and exit damper doors of other channels, and open the ash pump of the tank car.

6. Judging the result of precoating according to the increase of pressure difference in the filter chamber, when the pressure drop of the corresponding channel increases to 200-300pa (pressure difference between the upper and lower parts of the pattern plate), sufficient precoating can be obtained. After putting the pre coated powder into operation, the system runs to the normal design parameters, and then the dust cleaning system of the dust collector is started, and the dust collector enters into normal operation.

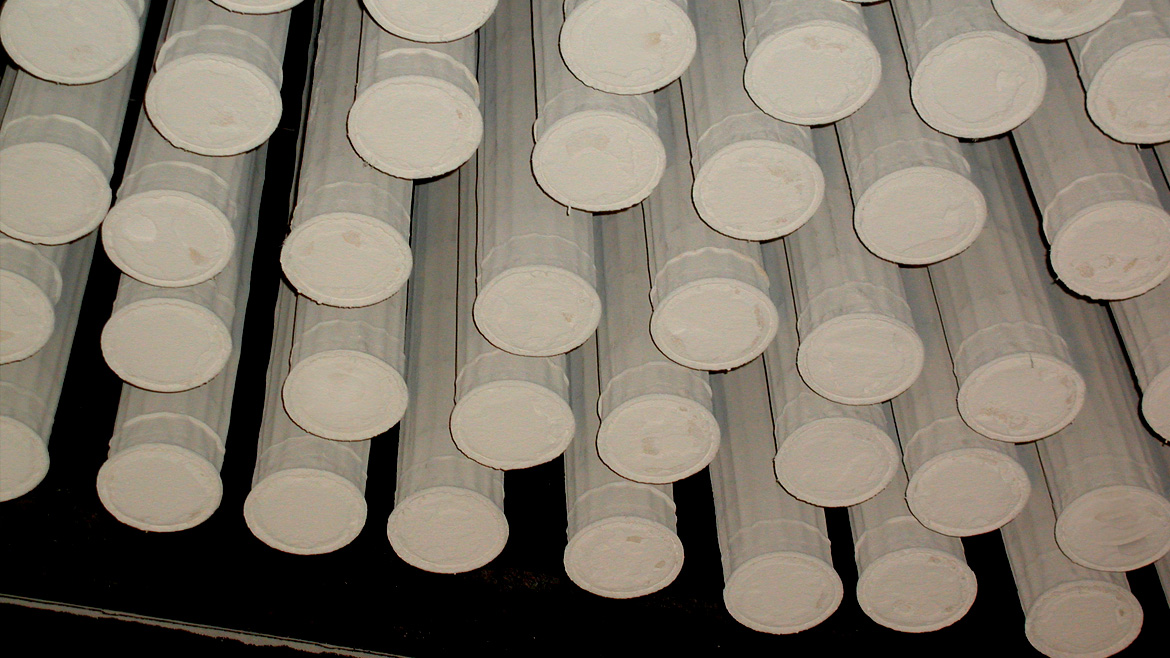

7. Check the uniformity of ash coating: personnel shall enter the clean gas chamber of the dust collector to check the condition of pre ash coating one by one. The method is to take out the filter bag for inspection. The standard is that the original outer surface of the bag cannot be observed. If uneven plastering is found, check the system, find out the cause, and repeat the pre plastering operation steps until the inspection is qualified.