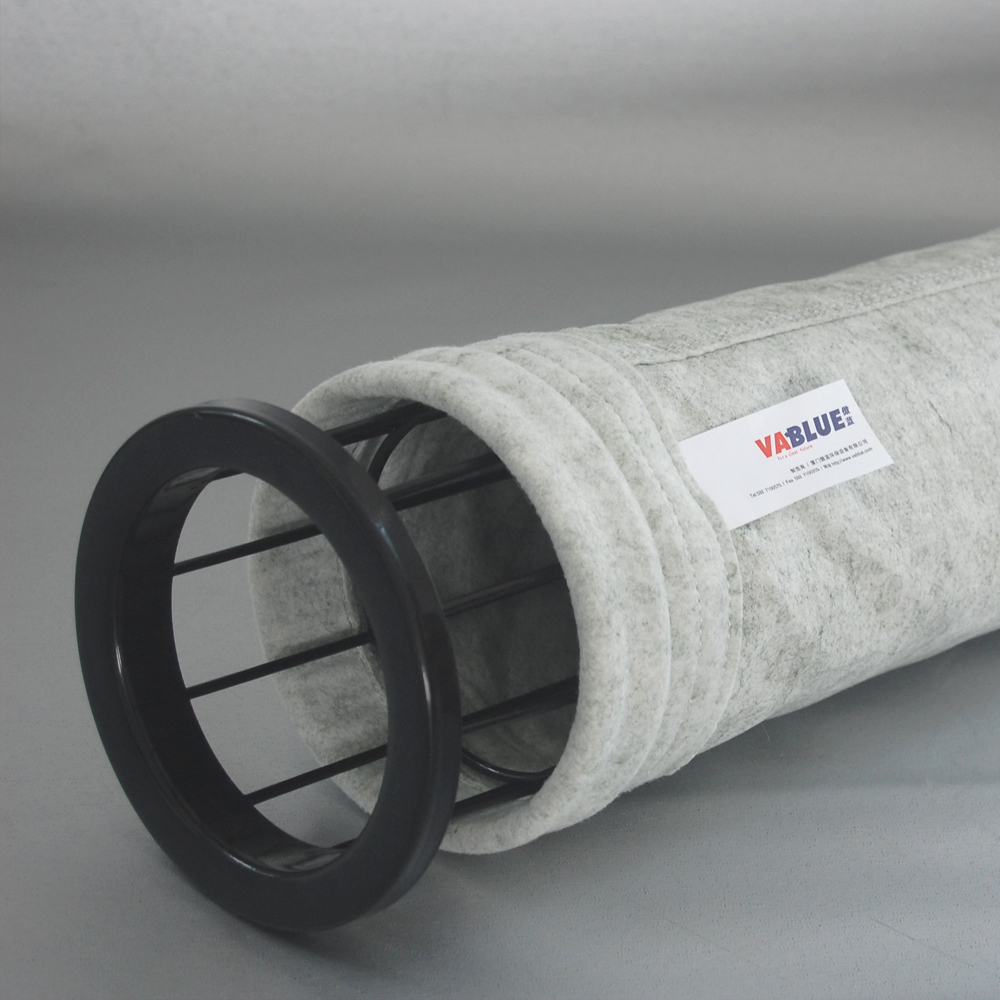

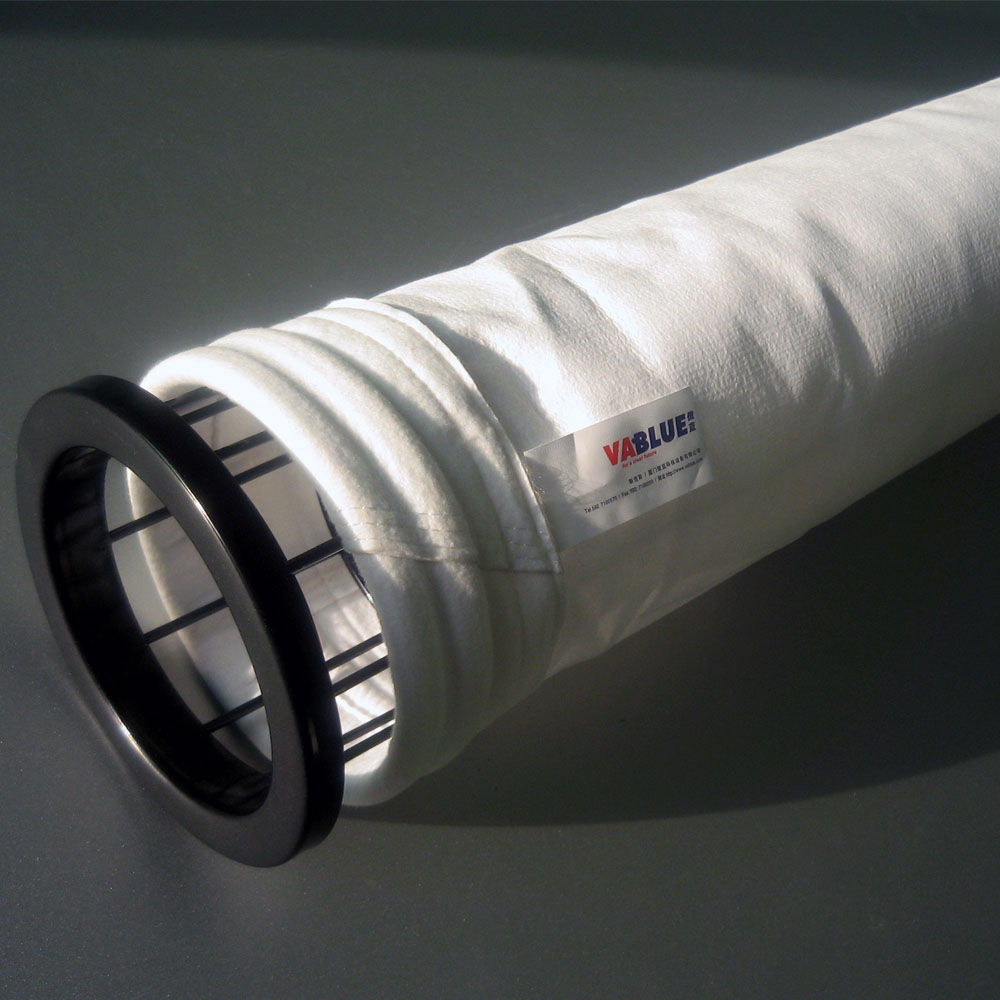

Description

After inserting conductive yarn or mixing conductive fiber and stainless steel fiber into the filter material, the filter material has the function of anti-static, which can be used for filtering static, explosive and flammable dust containing flue gas. When the concentration of general industrial dust reaches a certain degree (i.e. explosion limit), it is easy to cause explosion and fire in case of electrostatic discharge spark or external ignition and other factors, such as flour dust, chemical dust, pulverized coal dust, etc. it is possible to explode in case of electrostatic discharge. In the field of bag type dust removal, if the dust needs to be collected by cloth bag, the filter material for processing the dust removal cloth bag is required to have anti-static property, which can release the electric charge accumulated on the dust containing gas and the surface of the filter material in the process of use, so as to prevent the spark caused by electric charge discharge from causing explosion.

There are three types of anti-static commonly used: stripe / grid anti-static, binary fiber anti-static and stainless steel fiber anti-static, which should be selected according to the actual working conditions.

Technical parameter

Gram weight 500 (g / m2)

Thickness 1.8 (mm)

Air permeability 15 (m3/ m2/ min)

Breaking strength (meridional) > 600

Breaking strength (latitudinal) > 1000

Continuous working temperature 130 ℃

The post-treatment methods are calendering, singeing or PTFE treatment

Surface resistance 4.8x10 9 Ω

Volume resistance 8.7x108 Ω

Friction potential (maximum) 250V

Friction potential (average) 183v

The surface electric core density is 3.4mc/m2

The half-life was 0.75s