The conventional emission leak detection generally refers to the project leak detection which is greater than or equal to 30mg / Nm3

Large bag filter is composed of thousands to tens of thousands of filter bags. It is very difficult to find a damaged filter bag. At present, China's investment in bag filter has already exceeded 100 billion yuan, and the filter bag accounts for 10% - 15% of the total investment in bag filter. The average replacement cycle of filter bag is 2-3 years, that is to say, the cost of replacing filter bag is more than 3 billion yuan every year. Not all the filter bags need to be replaced every time when they are replaced. Only a few of them are damaged. Most of the filter bags are intact. If the damaged filter bags are detected and repaired or replaced, the overall replacement cycle of the filter bags can be extended and the filtration efficiency of the dust collector can be guaranteed.

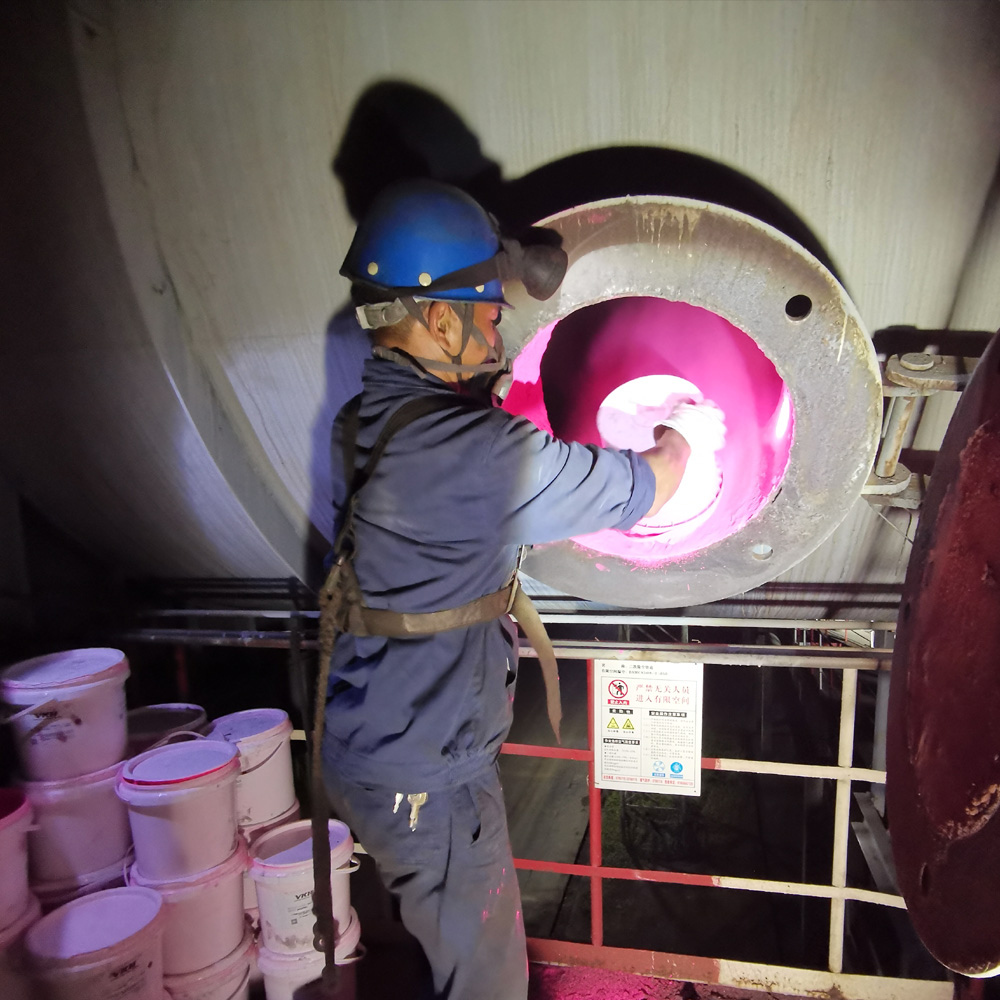

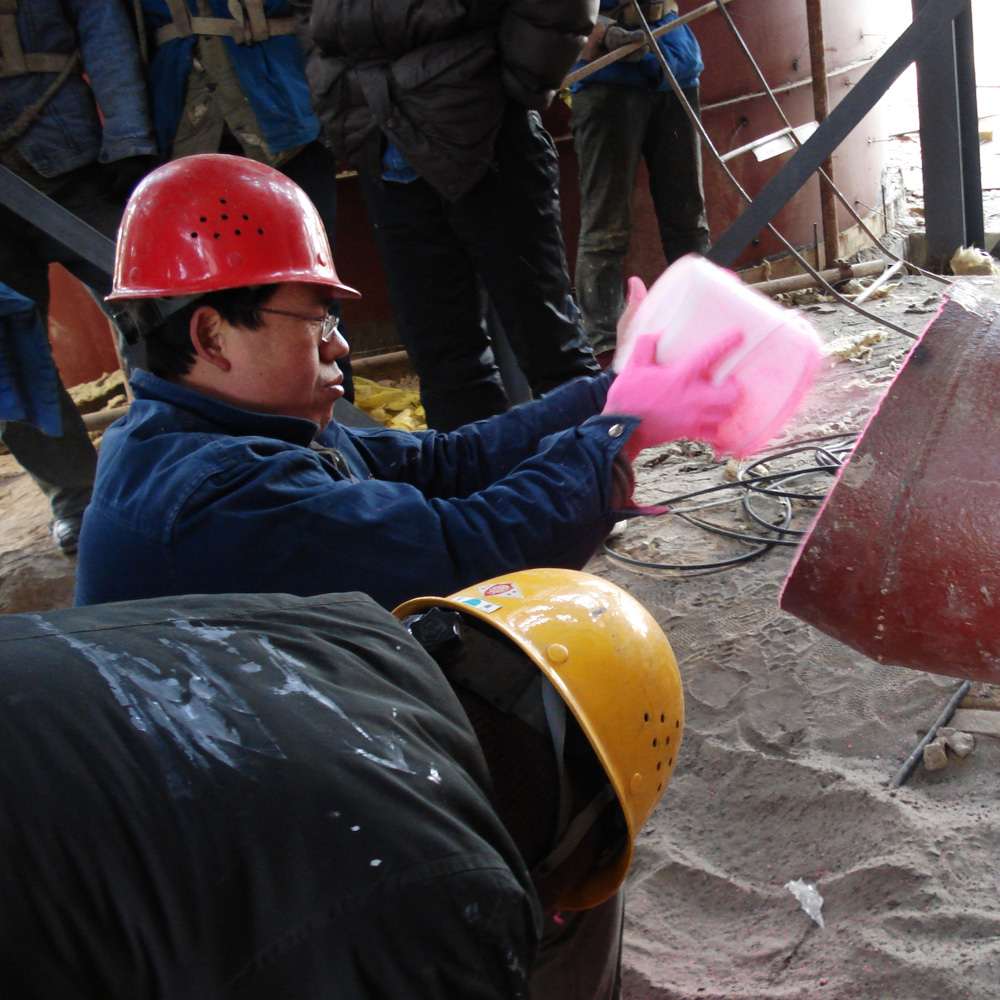

The new technology of fluorescent leak detection for dust collector is to inject the measured appropriate amount of fluorescent powder into the front end of the bag dust collector. Depending on the characteristics of the fluorescent powder accumulated in the leakage area with small resistance, the specific leakage position can be quickly found by special fluorescent lamp. After the popularization and application of this technology, not only the operation is simple, economical and reliable, the maintenance personnel can quickly, efficiently and accurately find the leakage point of the dust collector box and bag, but also the online monitoring data fluctuation of the dust collector is effectively avoided, the ultra-low emission of the dust collector is ensured, and the spare parts and maintenance costs are greatly saved.