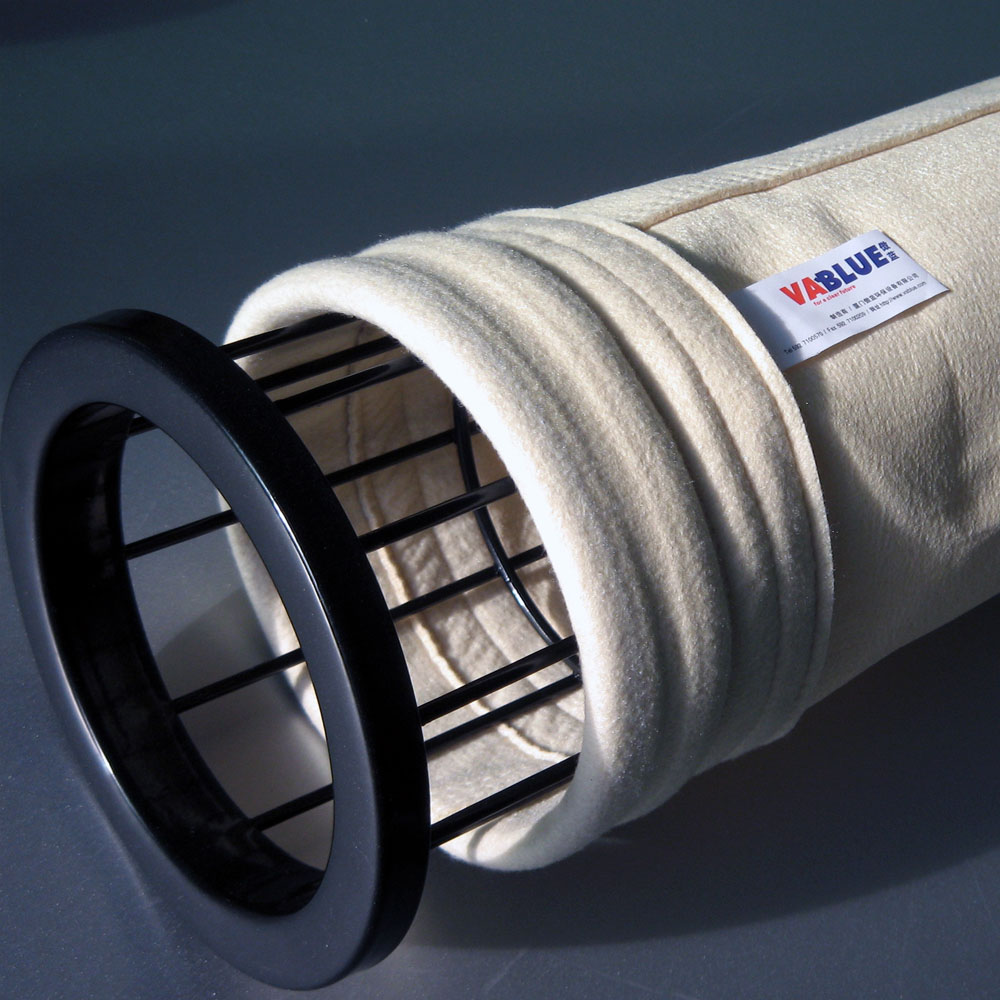

Description

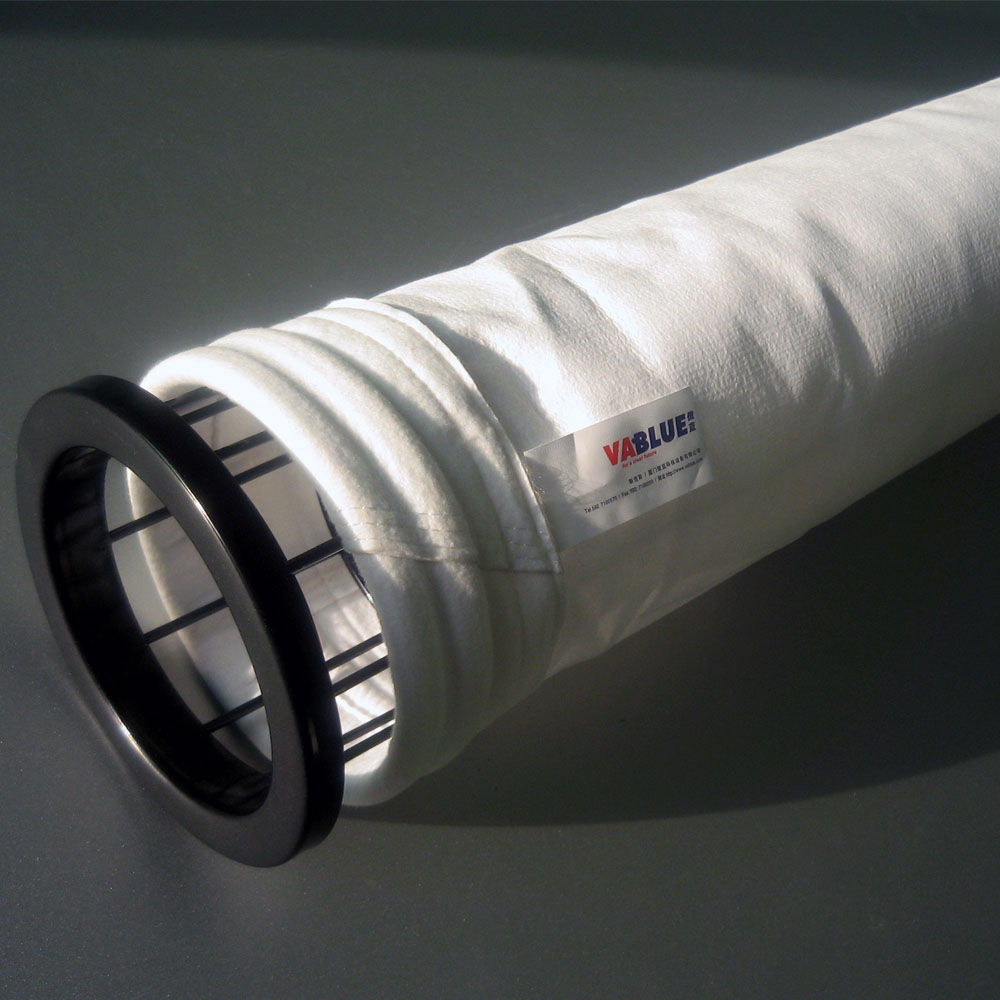

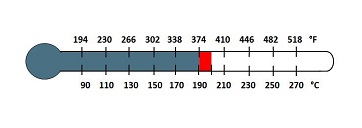

The operating temperature of PPS is 160 ℃ - 190 ℃. PPS has excellent heat resistance, acid-base resistance and hydrolysis resistance. It is also a good flame retardant filter material with good thermal stability. However, PPS has poor oxidation resistance and is prone to oxidative corrosion.

Maximum Continuous in Dry Conditions: 190°C / 374°F

Maximum Surge in Dry Conditions: 200°C / 392°F

Typical applications

PPS is widely used in coal-fired boiler, also used in waste incinerator, coke oven, kiln, chemical drying process of flue gas purification. It is also used in carbon black, powder collection, pneumatic conveying and cement industry.

Technical parameter

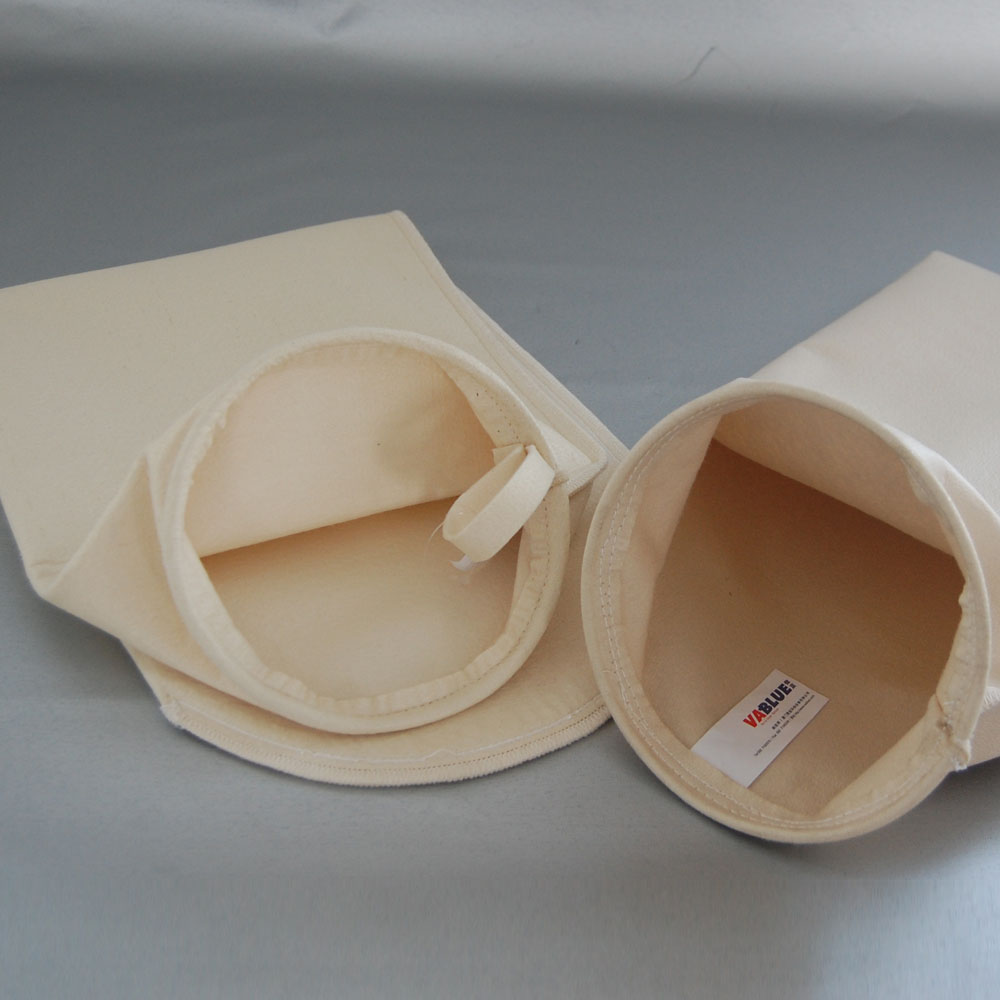

Product name PPS / PPS a500sg

Fiber 100% PPS

Base cloth 100% PPS

Weight per square gram 500g / m2

Thickness 1.8mm

Air permeability 130L / dm2.min

Fracture strength - longitudinal ≥ 800 n / 5cm

Fracture strength - transverse ≥ 1000 n / 5cm

Elongation @ 200N / 5cm - longitudinal < 5%

Elongation @ 200N / 5cm - transverse < 5%

Thermal shrinkage @ 210degc, 90min 1%

Blasting strength > 300 n / cm2

Service temperature

Continuous working temperature 160 ℃

Instantaneous working temperature 190 ℃

After treatment, heat setting, burning and pressing