Description

Aramid operating temperature 200 ℃ - 240 ℃. It has excellent flame retardancy, good alkali corrosion resistance, good thermal stability, abrasion resistance and bending resistance. However, the hydrolysis resistance of aramid fiber is poor. When there is Sox and water vapor in the flue gas or dew point often occurs, its service life will be greatly reduced. The condition that polyester cannot be used because of high temperature can be replaced by aramid.

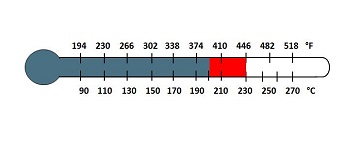

Maximum Continuous in Dry Conditions: 200°C / 392°F

Maximum Surge in Dry Conditions: 230°C / 446°F

Typical applications

Aramid is mainly used for flue gas purification in cement, asphalt road construction, cupola in foundry industry, blast furnace gas, recycled aluminum smelting, lime shaft kiln, carbon black, biomass power generation and other industries.

Technical parameters:

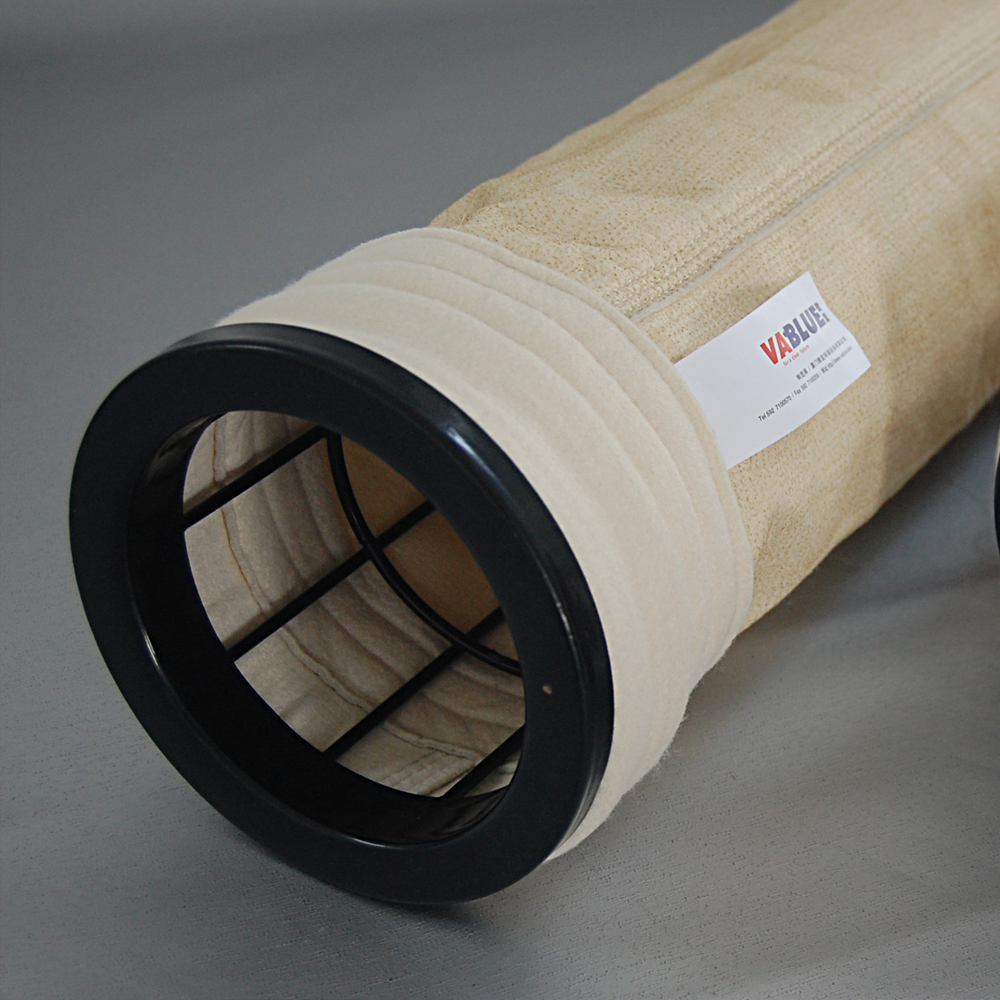

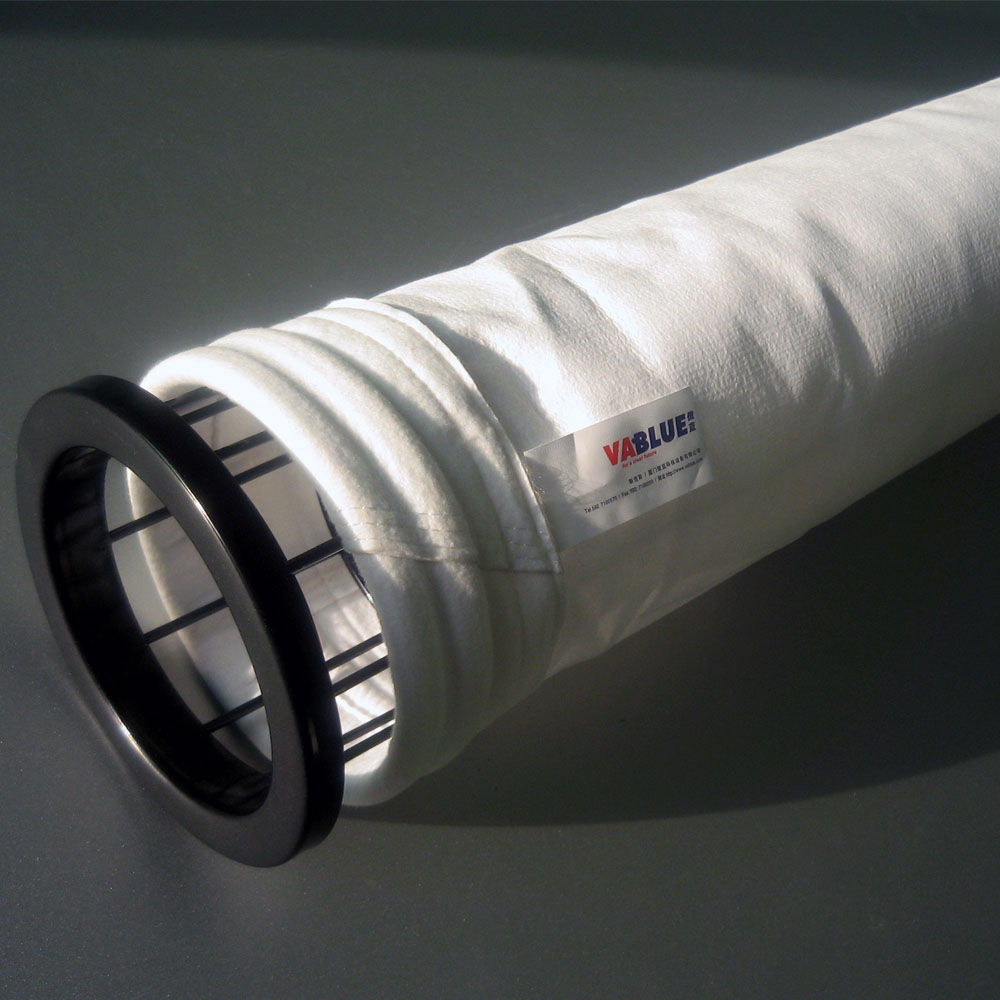

Product name AR / AR a500sg

Fiber 100% aramid

Substrate 100% aramid

Weight per square gram 500g / m2

The thickness is 2.1 mm

Density 0.24g/cm3

Air permeability 150L / dm2.min

Fracture strength - longitudinal ≥ 800 n / 5cm

Fracture strength - transverse ≥ 1000 n / 5cm

Elongation @ 200N / 5cm - longitudinal < 5%

Elongation @ 200N / 5cm - transverse < 5%

Thermal shrinkage @ 250degc, 90min 1%

Blasting strength > 300 n / cm2

Service temperature

Continuous working temperature 200 ℃

Instantaneous working temperature 240 ℃

Post treatment burning and pressing treatment